Thanks for the words of encouragement Mike - hopefully the rest will turn out as well [:)]

The weather has been so bad here that we've been unable to unload the shell and so i have not been able to take any good photos but the company who stripped & dipped the body sent me some pictures of the shell part way through the process - it had been stripped but not yet e-coated

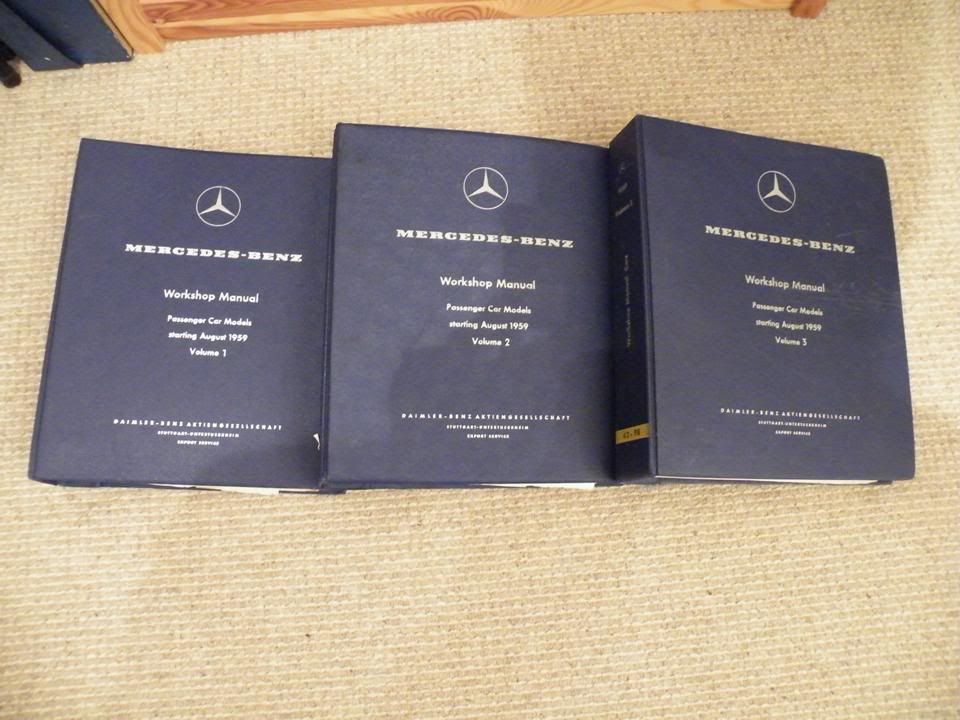

While the shell was away i made a start on the axle , Ron had kindley sent me a copy of the relevent pages from the manual for the axle and advised on what manual to look out for. After a bit of seaching i found a set for sale in the US (a bit expensive but well worth it)

The pages look like have never been used & i plan to scan them and then i can print off a copy to use in the workshop.

I stripped the axle completely & anything worn was replace. It was suprising how little wear there was - the crownwheel & pinion look like new !

Putting the rollers back in the slip joint is not a nice job - it took ne nearly an hour.

I'd had a discusion with the owner about the finish wanted of the suspension components and both of us had said that we did not want the parts high gloss - more semi gloss/satin as per the originals. After a bit of hunting i came across a Glasurit paint - Mercedes Benz semi gloss chassis black - MB9124 . This was a commercial vehicle chassis paint - just right to withstand the English weather [:)]

The only problem i've run into so far are the 2 bronze bushes the axle pivots on - there NLA from Mercedes & seem to be a custom size so i'm having 2 made specially by a specialist.