The clutch situation is getting really bizarre. The way I found the clutches in my transmission is completely off from the way it should be according to my manual.

The manual I am using is a German supplement for PKW Typen ab 1968, Baureihe 108-115, from January 1972. The header: Automatische Getriebe K4B 050, Typ 300 SEL/8 6.3

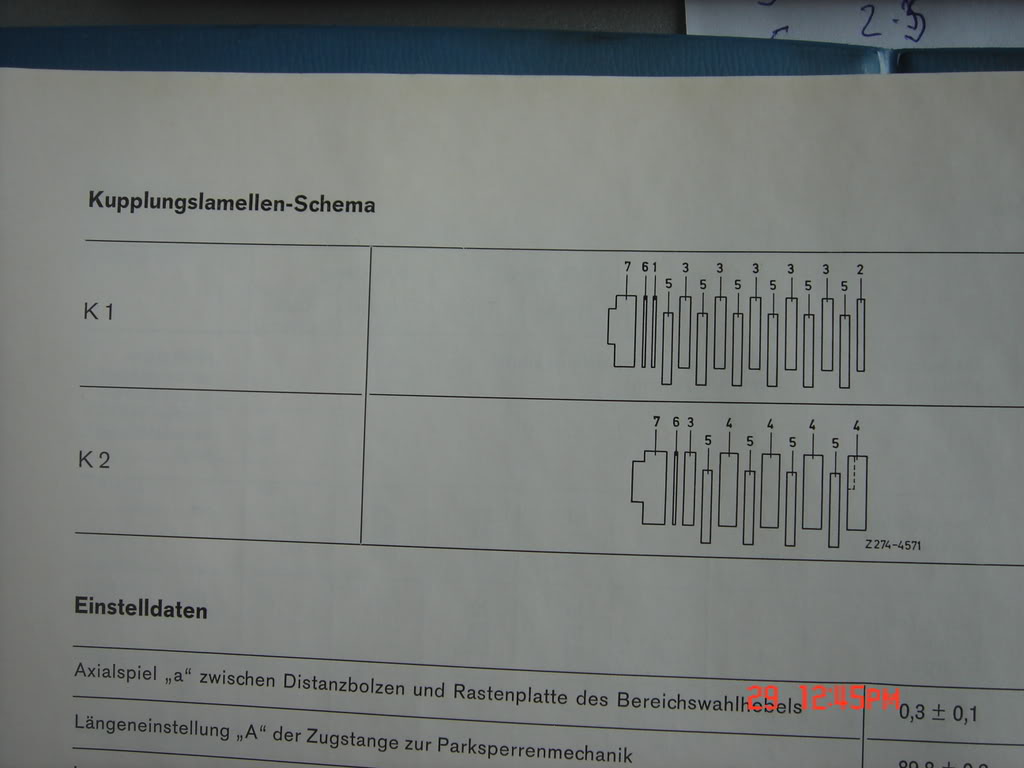

On page 27-10/4 it shows the clutch layout for both clutches:

K1: 6 1 5 3 5 3 5 3 5 3 5 3 5 2

K2: 6 3 5 4 5 4 5 4 5 4

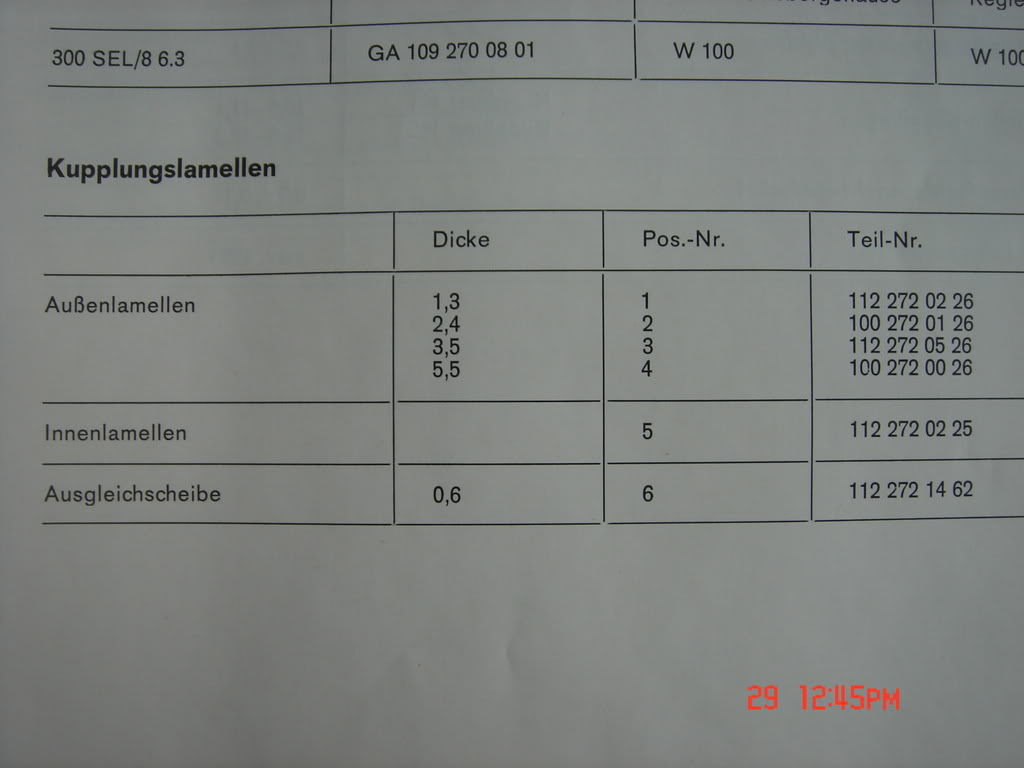

1 Steel 112 272 02 26 1.3mm

2 Steel 100 272 01 26 2.4mm

3 Steel 112 272 06 26 3.5mm

4 Steel 100 272 00 26 5.5mm

6 Steel 112 272 14 62 0.6mm

5 clutch plate lined 112 272 02 25 2.5mm

That means K1 has 14 elements with a total thickness of 36.8mm, and K2 has 10 elements with a total thickness of 36.1mm.

What I found:

K1:

3.0 Steel P

2.2 Lined

5.5 Steel P

2.3 Lined

5.0 Steel P

2.4 Lined

5.0 Steel F

2.3 Lined

4.5 Steel P

2.4 Lined

3.5 Steel F

K2:

4.5 Steel P

2.5 Lined

3.5 Steel F

2.5 Lined

3.5 Steel F

2.5 Lined

3.5 Steel F

2.5 Lined

3.5 Steel F

2.5 Lined

6.3 Steel F

Steel F is a steel plate with full teeth on the outside diameter, Steel P has 4 times 3 teeth on the outside diameter, Lined are the clutch plates lined with the friction material.

What we can see in K1 is that most lined clutch plates are worn down from their 2.5mm initial thickness, while in K2 these lined clutch plates are all still 2.5mm.

Also, both K1 and K2 have 11 elements. If you take the full 2.5mm for all clutch plates, K1 ends up being 39mm and K2 37.3mm. That is 2.2mm difference from the spec for K1 and 1.2 mm for K2. That is definitely outside of the tolerance, which is 0.6mm for K1 and 0.4 mm for K2.

What we also see is the in both clutches:

- The first 0.6mm steel plate is missing.

- K1 should have 6 lined plates, I have 5.

- K2 should have 4 lined clutch plates, I have 5

- K1 should have 3.5mm steel plates between the lined plates, I have a variety.

- K2 should have 5.5mm steel plates between the lined plates, I have the 3.5 mm ones.

I thought I might have confused K1 and K2, but that is definitely not the case, I have many pictures on how this came apart, and it is very obvious where each pack came from. The housing and pistons for K1 and K2 are completely different.

The only conclusion I can draw is that the previous rebuilder messed things up pretty bad. The fact that the K1 plates are way more worn down than the K2 ones also might be an indication that things were wrong, since K1 should have had 6 plates.

Any one have any ideas???

1965 600 SWB #248

1968 6.3 #0347

1971 6.3 #5745 Euro

1979 6.9 #6857 Euro

1979 450SLC 5.0 EURO

1981 300SD

1989 560SEL

2003 CL600 Brabus 570HP